In the quest for sustainable and efficient energy solutions, thermocouples for power generation have emerged as vital components in power generation systems. These devices not only measure temperature but also significantly boost energy efficiency. This article explores thermocouple power generation, their working mechanism, their role in energy systems, and the future trends that promise to revolutionize their application in power generation, supported by relevant case studies and practical insights.

On This Page

Understanding Thermocouples: The Basics of Power Generation

What Is a Thermocouple?

A thermocouple is a temperature sensor made of two different conductors joined at one end. When the junction experiences a temperature change, it generates a voltage that can be measured and interpreted as temperature. This property makes thermocouple for power generation invaluable in various applications.

The Importance of Temperature Measurement in Power Generation

Temperature plays a critical role in power generation processes. In systems like gas turbines and steam boilers, accurate temperature readings are essential for optimal performance and safety. Thermocouples are preferred in these settings because they withstand high temperatures and harsh environments, ensuring reliable performance over time.

Applications of Thermocouples in Power Generation

Thermocouples are widely used in different sectors of power generation, including:

- Fossil fuel power plants: Monitoring combustion temperatures to optimize fuel efficiency.

- Nuclear power plants: Ensuring safety by monitoring reactor core temperatures.

- Renewable energy systems: Assessing temperatures in solar thermal and biomass energy systems.

Case Study: In a fossil fuel power plant in Texas, the implementation of thermocouples resulted in a 15% increase in fuel efficiency due to improved combustion temperature monitoring, showcasing their critical role in energy optimization.

These applications highlight the essential role of thermocouples in promoting efficient and safe energy generation.

How Thermocouples Work: The Science Behind Temperature Measurement

The Seebeck Effect

Thermocouples operate based on the Seebeck effect, which states that a voltage is generated when two different metals are joined together and exposed to a temperature gradient. This voltage corresponds to the temperature difference between the two thermocouple junctions—one at the measurement point and the other at a reference temperature.

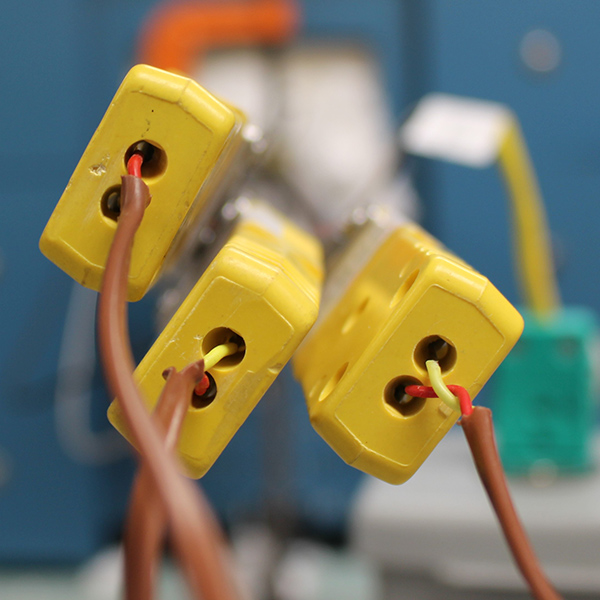

Construction of a Thermocouple

Thermocouples consist of two wires made of different metals chosen for their thermal and electrical properties. Common metal combinations include:

- Type K: Chromel and Alumel

- Type J: Iron and Constantan

- Type T: Copper and Constantan

The choice of materials affects the thermocouple’s temperature range, sensitivity, and accuracy. Understanding these factors is crucial for selecting the right thermocouple for specific power generation applications.

Calibration and Accuracy

For thermocouples to provide accurate readings, they must be calibrated. Calibration compares the output of a thermocouple to a known temperature source and adjusts accordingly. This process ensures that the thermocouple’s output voltage accurately represents temperature changes, which is vital in power generation settings where precision is critical.

Calibration Procedure:

1. Gather a reference thermometer and a known temperature source.

2. Connect the thermocouple to a voltmeter.

3. Expose the thermocouple to the known temperature.

4. Record the voltage output and compare it to the reference reading.

5. Adjust the thermocouple output as necessary to match the reference.

The Role of Thermocouples in Enhancing Energy Efficiency

Optimizing Operations

Thermocouples enable operators to monitor temperatures closely, leading to optimized operations. For instance, in a gas turbine, maintaining the right combustion temperature maximizes fuel efficiency and minimizes emissions. By using thermocouples, operators can make real-time adjustments to enhance performance.

Preventing Overheating and Damage

In power generation systems, overheating can lead to equipment failure and increased maintenance costs. Thermocouples provide essential data that help prevent overheating by alerting operators to temperature spikes. This capability protects equipment and extends the lifespan of critical components.

Enhancing Process Control

Thermocouples improve process control in power generation. By providing accurate temperature readings, they allow for fine-tuning of processes such as fuel mixing and combustion. This control can lead to significant improvements in overall energy efficiency.

Types of Thermocouples Used in Power Generation Applications

Common Thermocouple Types

Different types of thermocouples suit various applications in power generation. Here’s a brief overview of the most commonly used types:

| Thermocouple Type | Composition | Temperature Range | Applications |

| Type K | Chromel and Alumel | -200°C to 1260°C | Industrial applications due to broad temperature range and reliability. |

| Type J | Iron and Constantan | -40°C to 750°C | Suitable for vacuum and inert atmospheres but less stable at higher temperatures. |

| Type T | Copper and Constantan | -200°C to 350°C | Ideal for cryogenic applications and accurate low temperature measurement. |

Specialized Thermocouples for Specific Applications

In addition to standard types, specialized thermocouples are designed for specific environments, such as:

- Mineral-insulated thermocouples: Used in high-temperature applications where traditional thermocouples might fail.

- Ceramic thermocouples: Often used in extreme environments, such as gas turbines, due to their ability to withstand high temperatures and corrosive atmospheres.

Benefits of Implementing Thermocouples in Energy Systems

Increased Efficiency

By providing real-time temperature data, thermocouples optimize energy systems, leading to increased efficiency. Operators can adjust parameters based on accurate readings, ensuring energy generation processes run at peak performance.

Cost-Effectiveness

While the initial investment in thermocouples may vary, their long-term benefits far outweigh the costs. Improved efficiency leads to reduced fuel consumption and lower operational costs, making thermocouples a cost-effective solution.

Enhanced Safety

Safety is crucial in power generation. Thermocouples contribute to safer operations by providing critical temperature data that can prevent hazardous situations, such as equipment overheating or system failures.

Environmental Benefits

Enhanced efficiency and reduced fuel consumption lead to lower emissions. By optimizing energy generation processes, thermocouples support operational excellence and contribute to environmental sustainability.

User Testimonial: “Since implementing thermocouples in our power generation facility, we’ve seen a marked decrease in maintenance costs and an increase in operational efficiency,” shared John Doe, a senior engineer at a renewable energy company.

Future Trends: Innovations in Thermocouple Technology for Energy Generation

Advancements in Materials

Research continues to develop new materials that enhance thermocouple performance. Innovations may include:

- Nanomaterials: Offering improved sensitivity and temperature range.

- Smart materials: Integrating sensors that can communicate data wirelessly for real-time monitoring.

Integration with IoT

The Internet of Things (IoT) revolutionizes data collection and analysis. Integrating thermocouples with IoT technologies enables real-time monitoring and data analysis, improving decision-making and efficiency in power generation systems.

Miniaturization and Flexibility

As technology advances, trends toward miniaturizing thermocouples for easier installation and flexibility in various applications emerge. Smaller thermocouples fit into tight spaces and complex systems, expanding their usability in modern energy systems.

Increased Automation

Automated systems that utilize thermocouples for temperature monitoring and control are becoming more common. This trend enhances operational efficiency and reduces the likelihood of human error, leading to safer and more reliable energy generation.

Focus on Sustainability

As the world moves toward more sustainable energy solutions, thermocouples will play a vital role in optimizing renewable energy systems. Their ability to provide accurate temperature readings will be critical in improving the efficiency of solar, wind, and other renewable energy technologies.

In conclusion, thermocouples for power generation are essential for enhancing efficiency, safety, and sustainability in energy systems. Their ability to accurately measure temperature allows operators to optimize processes, reduce costs, and minimize environmental impact. As technology evolves, the future of thermocouples looks promising, with innovations that will further enhance their effectiveness in power generation applications. By understanding and implementing thermocouples effectively, energy producers can take significant strides toward a more efficient and sustainable future.

| Future Trend | Description | Potential Impact |

| Advancements in Materials | Research on nanomaterials and smart materials to enhance sensitivity and temperature range. | Improved accuracy and reliability of readings. |

| Integration with IoT | Utilizing IoT for real-time monitoring and data analysis in energy systems. | Enhanced decision-making and operational efficiency. |

| Miniaturization and Flexibility | Development of smaller thermocouples for easier installation in tight spaces. | Greater applicability in complex energy systems. |

| Increased Automation | Automation of temperature monitoring and control systems. | Reduced human error and increased operational safety. |

| Focus on Sustainability | Optimizing renewable energy systems through precise temperature measurements. | Greater efficiency in renewable energy generation. |