On This Page

Finding Plastic Fabrication Companies Near Me

What Is Plastic Fabrication?

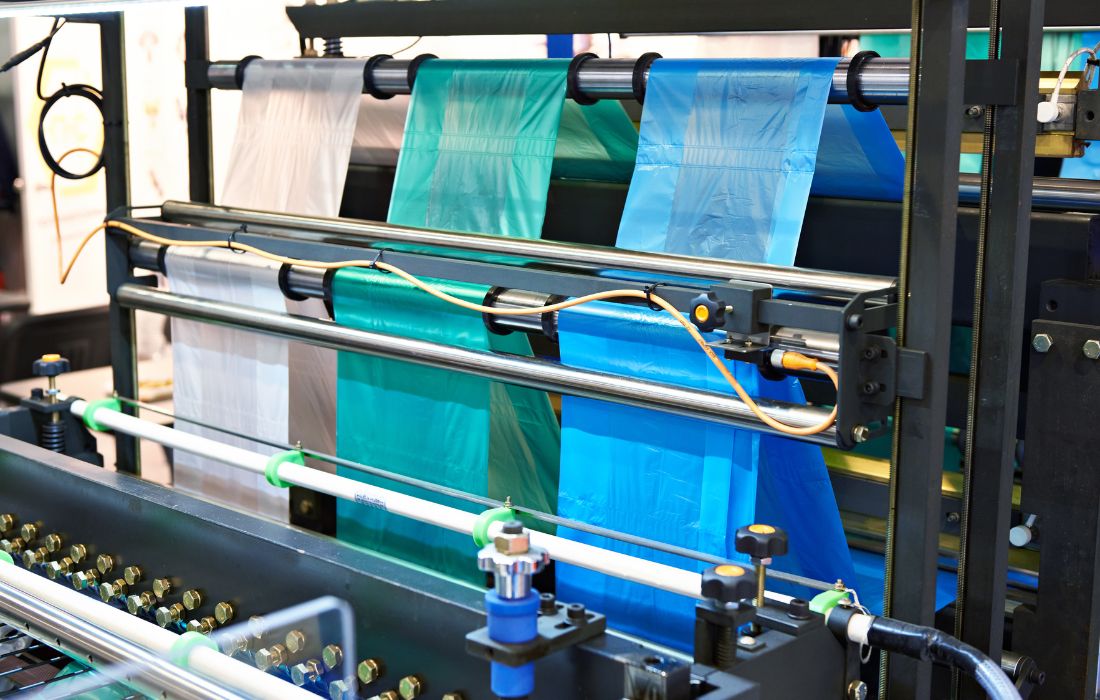

Plastic fabrication involves creating products from plastic materials using various methods, including molding, machining, and assembly. Understanding these processes is crucial before you search for companies, as it allows you to express your needs clearly. For instance, processes like injection molding are ideal for mass production of complex parts, while CNC machining is suited for precision and customization.Types of Projects That Require Plastic Fabrication

Different projects require various types of plastic fabrication. Here are some common applications:Industrial Applications

- Machinery Parts: Industries frequently need custom plastic parts, such as gears and housings, which can enhance performance and longevity.

- Safety Guards: Plastic safety guards protect machinery and workers, ensuring compliance with safety standards.

Consumer Products

- Packaging: Custom plastic packaging is vital for product safety and visual appeal, often enhancing marketability.

- Household Items: Everyday products, from storage bins to furniture, often rely on plastic fabrication for durability and design.

Medical Devices

- Surgical Instruments: High-grade plastics are commonly used in surgical tools for safety and sterility.

- Implants: Biocompatible plastics are crucial in medical implants to ensure patient safety.

Assessing Your Specific Requirements

To communicate your needs effectively to plastic fabrication companies, consider the following:- Material Type: What kind of plastic do you require? Options include acrylic, PVC, and polypropylene, each serving different applications.

- Quantity: Are you looking for a single prototype or mass production?

- Timeline: What deadlines do you have for project completion?

- Budget: What is your budget? Understanding this helps in choosing the right company.

Key Factors to Consider When Selecting Plastic Fabrication Companies

Proximity and Convenience of a Plastic Manufacturer Near Me

Choosing plastic fabrication companies near me offers significant advantages:- Faster Communication: Local companies often respond more quickly to inquiries and changes, enhancing project agility.

- Easier Logistics: Working with plastic manufacturer near me simplifies logistics, reducing shipping times and costs.

Industry Experience and Reputation

Experience Matters

Select companies with a solid track record in your specific industry. Experienced companies understand the challenges and requirements of your project. For example, a company specializing in medical devices will have insights into the specific regulations and testing required for those products.Customer Reviews and Testimonials

Research online reviews and testimonials to gauge company reputation. Companies with positive feedback from past clients are likely to provide quality service.Certifications and Industry Standards

Quality Assurance Certifications

Verify that the company adheres to industry standards, such as ISO certifications. These certifications indicate a commitment to quality and continuous improvement.Safety Compliance

Confirm whether the company meets relevant safety regulations for your industry. This is particularly crucial for medical and food-related products.Preparing for Your Consultations

Crucial Questions to Ask

Before meeting with potential plastic fabrication companies, prepare questions to assess their fit for your project. Here are some examples:What Materials Do You Work With?

– Knowing the available materials helps you determine if they can meet your needs.What Is Your Lead Time?

– Understanding fabrication timelines is essential for planning your project.Do You Provide Prototyping Services?

– Confirm if they can produce a prototype before mass production, which is critical for testing designs.What Are Your Quality Control Procedures?

– Ask how they ensure product quality. A reliable company should have robust quality control measures.Evaluating Responses

As you meet with different plastic fabrication companies, take notes and compare their answers. Look for companies that show a clear understanding of your needs and take a proactive approach to solving problems.| Factor | Description | Importance |

| Material Type | Identifying the specific type of plastic required for your project (e.g., acrylic, PVC). | Ensures the right properties for your needs. |

| Quantity | Determining whether you need a prototype or mass production. | Impacts manufacturing process and cost. |

| Timeline | Establishing deadlines for project completion. | Affects planning and scheduling. |

| Budget | Outlining your financial constraints for the project. | Helps in selecting a suitable company. |

| Prototyping Services | Checking if the company offers prototyping before mass production. | Essential for testing and validation. |

| Quality Control Procedures | Understanding the measures in place for maintaining product quality. | Ensures reliability and compliance. |

| Lead Time | Knowing the expected time frame for production and delivery. | Critical for project timelines. |

| Customer Feedback | Researching reviews and testimonials from previous clients. | Provides insight into the company’s reliability. |