On This Page

Understanding Medical Wire: Types and Applications

What is Medical Wire?

Medical wire is a specialized wire used in the production of various medical devices, designed to meet stringent performance and safety standards for healthcare applications. Common materials include stainless steel, nickel-titanium alloys, and other biocompatible substances.Types of Medical Wire

Several types of medical wire exist, each tailored for specific applications: Guide Wires: These wires assist in navigating blood vessels or other anatomical structures during minimally invasive procedures. They must be precise, flexible, and strong. Suture Wire: Used in surgical sutures, this wire requires good tensile strength and biocompatibility to avoid adverse reactions in the body. Electrode Wire: Commonly found in devices that monitor or stimulate nerves or muscles, electrode wires must conduct electricity effectively while remaining flexible. Stent Wire: These wires support stents that keep blood vessels open. They need to be strong and corrosion-resistant.Applications of Medical Wire

Medical wire serves various medical devices, including:- Cardiovascular Devices: Such as stents and catheters.

- Orthopedic Devices: Including pins and screws for bone fixation.

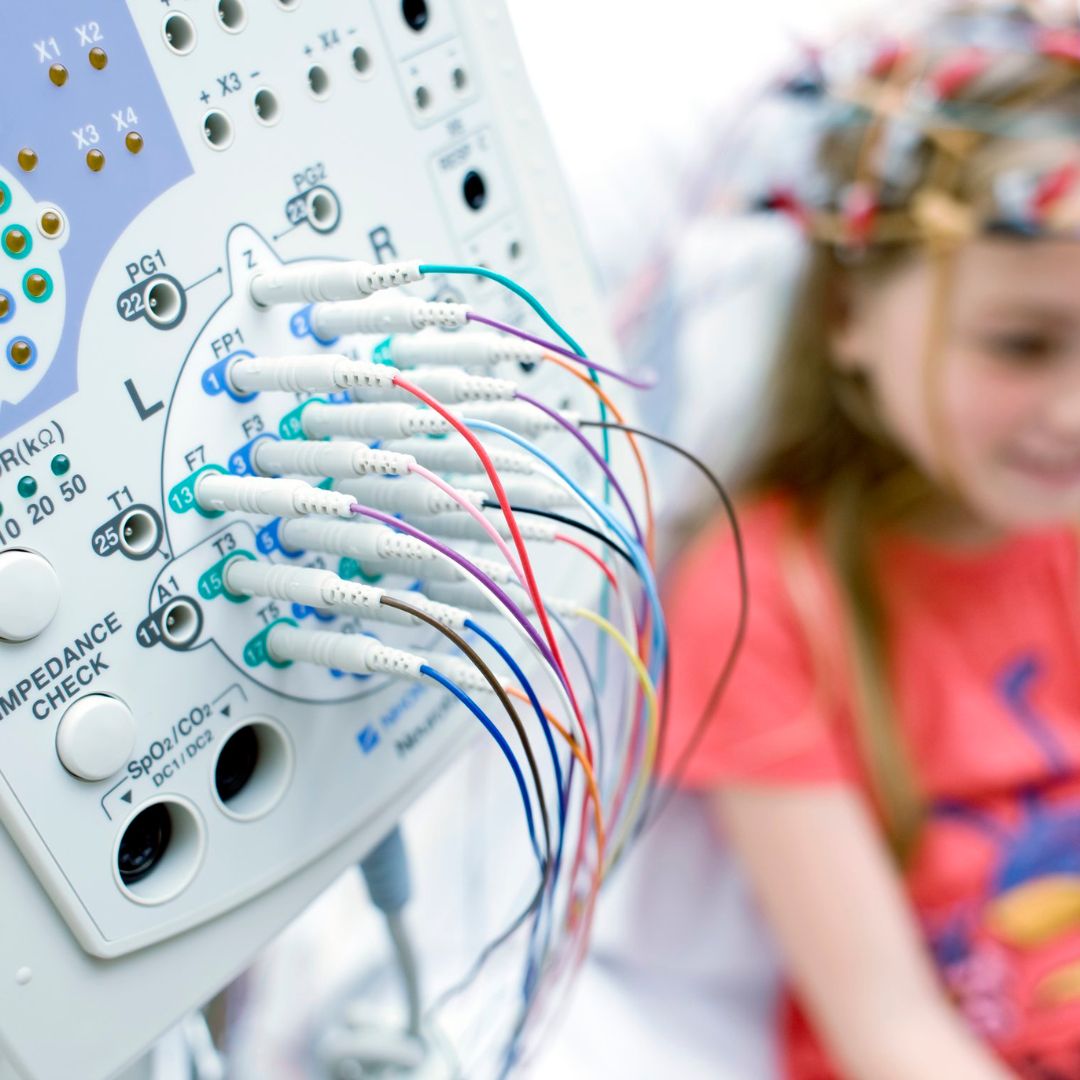

- Neurological Devices: Such as electrodes and neurostimulators.

- Surgical Instruments: Including tools for suturing and tissue repair.

Supplier Selection: Key Factors for Sourcing Quality Medical Wire Manufacturers

Selecting the right medical wire manufacturers is crucial when sourcing medical wire. Consider these key factors:Reputation and Experience

Choose suppliers with a solid reputation and extensive experience in the medical industry. Established companies often have a proven track record in quality and compliance. For instance, a well-regarded supplier might have successfully validated its products through extensive testing and client feedback.Quality Assurance

Verify that the manufacturer follows strict quality control processes. Look for certifications like ISO 13485, which show adherence to high standards in medical device manufacturing. An example of a reputable supplier is Medtronic, known for its rigorous quality assurance practices.Customization Capabilities

Medical devices require different wire specifications. A reliable supplier should customize wire to your needs, including diameter, coating, and mechanical properties. For example, some suppliers offer tailored solutions for specific surgical applications, enhancing the overall effectiveness of the devices.Technical Support

Access to technical support is vital. Suppliers offering guidance on material selection, design considerations, and regulatory compliance can significantly aid the development process, ensuring that manufacturers can navigate complex regulatory landscapes effectively.Material Matters: Choosing the Right Composition for Medical Devices

The composition of medical wire is critical to its performance. Different materials offer various benefits and drawbacks, making it essential to choose the right one for your device.Common Materials Used by Medial Wire Suppliers

Stainless Steel: Known for its strength, corrosion resistance, and biocompatibility, it is suitable for guide wires and sutures. Its use in surgical applications has been well-documented in clinical studies. Nickel-Titanium Alloys: These alloys are known for their superelasticity and shape memory, often used in stents and guide wires. Their unique properties allow for minimally invasive procedures that were previously impossible. Polymer Coatings: Some medial wire suppliers coat the medical wire with biocompatible polymers to enhance performance, improving lubricity and reducing friction during procedures.Considerations for Material Selection

When choosing materials for medical wire, consider:- Biocompatibility: The material must be compatible with biological tissues.

- Mechanical Properties: Assess strength, flexibility, and fatigue resistance.

- Corrosion Resistance: Ensure the material withstands exposure to bodily fluids and sterilization processes.

Regulatory Compliance: Ensuring Your Medical Wire Meets Standards

Compliance with regulatory standards is essential in the medical device industry. Here’s what you need to know:Key Regulatory Bodies

Medical wires must comply with regulations set by authorities.Importance of Documentation

Proper documentation is vital for regulatory compliance. Ensure that your supplier provides:- Certificates of compliance

- Test reports for biocompatibility

- Manufacturing process documentation

Mechanical Properties: Evaluating Strength and Flexibility in Medical Wire

The mechanical properties of medical wire are crucial for its performance. Here are the key properties to consider:Strength

Tensile strength determines a wire’s ability to withstand forces without breaking. This property is critical for applications such as guide wires and stents, where high strength is necessary to navigate complex anatomical structures.Flexibility

Flexibility is essential, especially for wires used in minimally invasive procedures. A flexible wire can navigate curves and bends without fracturing, making it easier to use in delicate operations.Fatigue Resistance

Medical wire must also show good fatigue resistance, meaning it can withstand repeated bending and flexing without failing. This property is particularly important in dynamic environments, such as heart stents, where wires are subjected to constant motion.Cost vs. Quality: Balancing Budget with Performance Needs

When selecting medical wire, balancing cost and quality is crucial. Here’s how to approach this dilemma:Understanding Total Cost of Ownership

While it may be tempting to choose the cheapest option, consider the total cost of ownership. This includes:- Initial purchase price

- Long-term durability and performance

- Potential costs associated with device failure or recalls

Investing in Quality

Investing in high-quality medical wire can lead to better performance and fewer complications, ultimately saving costs in the long run. High-quality materials often result in more reliable devices, reducing the risk of litigation or regulatory issues.Cost-Effective Alternatives

If budget constraints exist, explore cost-effective alternatives without compromising quality. Discuss your needs with suppliers, who may offer different materials or manufacturing processes that meet your requirements at a lower cost.Manufacturing Processes that Affect Medical Wire Selection

The manufacturing processes used to create medical wire significantly impact its quality and performance. Understanding these processes can help you make better decisions.Wire Drawing

The initial step in creating medical wire is wire drawing, where metal rods are drawn through a series of dies to reduce their diameter. This process influences the wire’s mechanical properties, such as strength and flexibility.Annealing

Annealing is a heat treatment that relieves stress and improves ductility. This process is crucial for medical wire, enhancing flexibility and reducing the risk of breakage during use.Coating

Coating processes can enhance medical wire properties. For instance, polymer coatings can improve lubricity, while metallic coatings can increase corrosion resistance. Choose a coating that aligns with the intended application of your medical wire.Future Trends in Medical Wire Technology for Innovative Devices

The medical wire industry continues to evolve, driven by technological advancements and changing healthcare needs. Here are some future trends to watch:Advanced Materials

Research into new materials, such as bioresorbable wires that dissolve in the body, is on the rise. These materials could transform how medical devices function, reducing the need for additional surgeries to remove them.Smart Medical Wires

Integrating smart technologies into medical wires is becoming more common. Sensors embedded in wires could provide real-time data on patient conditions, improving monitoring and treatment outcomes.Sustainable Manufacturing

As sustainability gains priority in manufacturing, medical wire suppliers are exploring eco-friendly materials and processes. This shift can reduce environmental impact and appeal to environmentally conscious consumers.Customization through 3D Printing

3D printing technology simplifies the customization of medical wire for specific applications. This technology allows for rapid prototyping and the creation of complex geometries that traditional manufacturing processes cannot achieve.| Key Consideration | Description | Examples of Impact |

| Types and Applications | Different types of medical wire are suited for specific applications, affecting device performance. | Guide wires for cardiovascular interventions |

| Supplier Selection | Choosing reputable suppliers ensures quality and compliance with standards. | Medtronic’s quality assurance practices |

| Material Choices | Material impacts biocompatibility, strength, and flexibility of medical wire. | Stainless steel vs. nickel-titanium alloys |

| Regulatory Compliance | Adherence to standards like ISO 13485 ensures safety and efficacy of medical devices. | Compliance documentation for FDA approval |

| Mechanical Properties | Key properties such as strength, flexibility, and fatigue resistance determine wire usability. | Guide wires navigating complex anatomy |

| Cost Considerations | Balancing initial costs with long-term performance and reliability is crucial. | Total cost of ownership analysis |

| Manufacturing Processes | Techniques like wire drawing and annealing influence wire characteristics and quality. | Impact of coating on lubricity and corrosion |

| Future Trends | Innovations such as smart wires and sustainable materials are shaping the future of medical devices. | Bioresorbable wires reducing surgical needs |