On This Page

Understanding the Basics of Rubber Formulation

Rubber formulation involves creating a specific mixture of raw materials to produce rubber with desired properties. The formulation typically includes natural or synthetic rubber, fillers, plasticizers, curing agents, and other additives that enhance performance.Types of Rubber

Different types of rubber serve various applications:- Natural Rubber (NR): Sourced from latex, offering high elasticity and resilience.

- Synthetic Rubber (SR): Derived from petrochemicals, tailored for specific uses, such as styrene-butadiene rubber (SBR) for tires.

- Thermoplastic Elastomers (TPE): Combines properties of rubber and plastic for versatile applications.

The Importance of Custom Rubber Compound Formulation

Custom rubber compound formulation allows manufacturers to tailor rubber properties to meet specific performance needs. Factors such as temperature resistance, tensile strength, and chemical resistance can be adjusted through careful selection and combination of ingredients.Key Components in Effective Rubber Formula

Understanding the key components is essential for creating high-quality rubber.Base Polymer

The base polymer forms the foundation of any rubber formula. The choice between natural and synthetic rubber depends on the desired properties and application. For example, SBR is popular in automotive tires due to its excellent abrasion resistance (Source: Rubber Manufacturers Association).Fillers

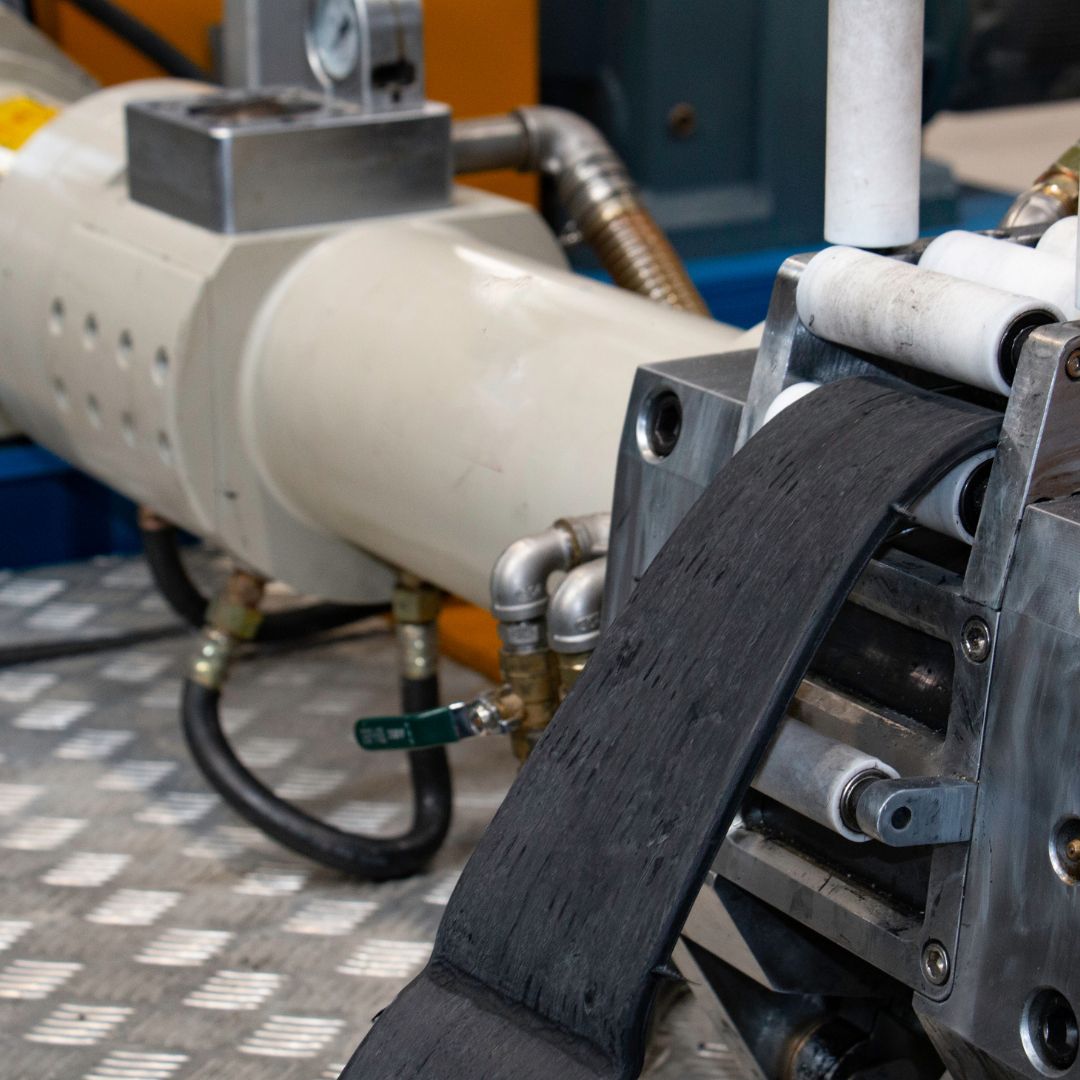

Fillers enhance the mechanical properties of rubber. Common fillers include:- Carbon Black: Boosts strength and durability.

- Silica: Improves wet traction and reduces rolling resistance.

- Clay and Talc: Increase stiffness and lower production costs.

Plasticizers

Plasticizers increase the flexibility and workability of rubber, reducing costs. Common plasticizers include mineral oils and esters.Curing Agents

Curing agents, or vulcanizing agents, are crucial for cross-linking rubber molecules, which enhances elasticity and heat resistance. Sulfur is the most commonly used curing agent, but alternatives like peroxides are also available for specific applications.The Role of Additives in Enhancing Performance

Additives are vital in rubber formulation as they improve performance characteristics.Antioxidants

Antioxidants prevent degradation from heat and oxygen, prolonging the life of rubber products.Accelerators

Accelerators speed up the curing process, allowing for efficient production times and optimal cross-linking, which affects the rubber’s final properties.Colorants

Colorants enhance the appearance of rubber and can provide UV protection.Reinforcements

Reinforcements, such as fibers or other materials, improve tensile strength and wear resistance.Common Challenges in Rubber Manufacturing and Solutions

Rubber manufacturing can present challenges that affect product quality and performance.Inconsistent Quality

Inconsistent material quality can lead to defects. Manufacturers should source raw materials from reputable suppliers and conduct regular quality checks.Production Costs

High production costs can hinder profitability. Implementing efficient processes and using cost-effective materials can help lower these costs.Environmental Regulations

Manufacturers must adhere to environmental regulations regarding emissions and waste. Adopting eco-friendly practices and sustainable materials can ensure compliance and appeal to environmentally conscious consumers.Importance of Testing and Quality Control in Formulation

Testing and quality control are crucial in rubber formulation to ensure the final product meets performance standards.Types of Tests

Several tests are performed throughout the rubber manufacturing process:- Physical Tests: These measure properties such as tensile strength, elongation, and hardness.

- Chemical Tests: Assess resistance to various chemicals and environmental factors.

- Performance Tests: Evaluate rubber performance under real-world conditions.

Quality Control Measures

Implementing strict quality control measures, such as statistical process control (SPC) and regular audits, helps maintain consistency and quality in rubber formulation.Innovations Shaping the Future of Rubber Formulation

The rubber industry continually evolves, with innovations enhancing formulation techniques and product performance.Advanced Materials

The development of advanced materials, such as nanocomposites, allows for improved strength and thermal resistance.Smart Rubber

Smart rubber technologies, incorporating sensors and other technologies, are emerging to create self-healing or adaptive rubber products that respond to environmental changes.3D Printing

3D printing technology revolutionizes rubber manufacturing by enabling rapid prototyping and customization of rubber components.Eco-Friendly Practices in Rubber Manufacturing

Sustainability is increasingly important in the rubber industry. Incorporating eco-friendly practices benefits the environment and enhances brand reputation.Sustainable Sourcing

Using sustainable raw materials, such as bio-based elastomers or recycled rubber, reduces the environmental impact of rubber manufacturing.Energy Efficiency

Implementing energy-efficient practices in manufacturing lowers energy consumption and operational costs.Waste Reduction

Adopting waste reduction strategies, such as recycling scrap rubber and minimizing production waste, supports sustainable operations.How to Optimize Your Production Process for Better Results

Optimizing the production process is essential for improving efficiency and product quality.Streamlining Processes

Reviewing and streamlining processes helps identify bottlenecks and reduce production times. Lean manufacturing principles can minimize waste and enhance productivity.Employee Training

Investing in employee training ensures your workforce is skilled in the latest techniques and technologies, improving quality and efficiency.Regular Maintenance

Regular maintenance on machinery ensures production equipment runs smoothly, reducing downtime and increasing output.| Innovation/Tip | Description | Benefits |

| Advanced Materials | Utilization of nanocomposites that enhance strength and thermal resistance. | Improved product durability and performance. |

| Smart Rubber | Incorporation of sensors to create adaptive rubber products. | Enhanced functionality and responsiveness. |

| 3D Printing | Use of 3D printing for rapid prototyping and customization of rubber components. | Increased design flexibility and efficiency. |

| Monitor Industry Trends | Staying informed on the latest advancements and materials in the rubber industry. | Competitive edge and innovation opportunities. |

| Customer Feedback | Engaging with customers to gather insights on product performance and desired improvements. | Better alignment with market needs. |

| Collaborate with Experts | Partnering with material scientists for advanced formulation techniques. | Access to cutting-edge knowledge and practices. |