Are there different types of thermocouples? Yes, thermocouples come in various types, each designed for specific applications and temperature ranges. Thermocouples are essential tools in various industries, known for their effectiveness in measuring temperature. Understanding the different types of thermocouples helps you choose the right one for your application. This article covers the basics of thermocouples, their construction, specific types, and best practices for installation and use.

On This Page

Understanding Different Types Of Thermocouples: The Basics of Temperature Measurement

Thermocouples convert thermal energy into electrical energy. They consist of two dissimilar metals joined at one end. When the junction changes temperature, it generates a voltage proportional to the temperature difference. This process is known as the Seebeck effect.

How Thermocouples Work

The principle of a thermocouple is straightforward. When the joined ends of two different metals heat up, they produce a voltage. This voltage, usually in millivolts, can be measured and translated into a temperature reading. Sensitive measuring equipment is necessary to detect this small voltage.

Applications of Thermocouples

Industries such as manufacturing, automotive, aerospace, and food processing widely use thermocouples. They are favored for their ability to measure a wide range of temperatures, durability, and cost-effectiveness. Understanding the different types of thermocouples available ensures accurate temperature measurements in your specific application.

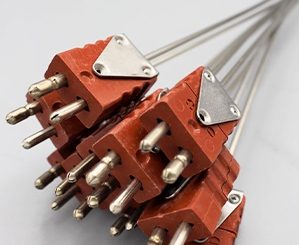

Types of Thermocouples: The Construction and Working Principles

Basic Components of a Thermocouple

A thermocouple has two primary components: the thermocouple wire and the thermocouple junction. The wire consists of two different metals, while the junction is where the two metals connect to form a measurement point.

Are There Different Types Of Thermocouples Junctions?

Are There Different Types Of Thermocouples Junctions? Yes. The junction can be a welded junction or a grounded junction. A welded junction, more common, offers better response times. A grounded junction is ideal for applications needing rapid measurements, as it allows direct contact with the medium being measured.

Factors Affecting Thermocouple Function

Several factors can impact thermocouple performance, including:

– The type of metals used

– The environment (e.g., corrosive or high-pressure)

– The thermocouple’s insulation

Type K Thermocouples: Versatility Across a Wide Range

Type K thermocouples are popular due to their versatility. They consist of Chromel (Nickel-Chromium alloy) and Alumel (Nickel-Aluminum alloy).

Temperature Range and Accuracy

Type K thermocouples measure temperatures from -200°C to 1260°C (-328°F to 2300°F). Their accuracy is typically within ±2.2°C or ±0.75% of the reading, whichever is greater.

Applications of Type K Thermocouples

These thermocouples are common in kilns, gas turbine exhaust, and other high-temperature applications. Their ability to withstand extreme conditions makes them a preferred choice in many industrial processes.

Type J Thermocouples: Ideal for Ferrous Metals Applications

Type J thermocouples, made of Iron and Constantan, excel in measuring ferrous metals.

Temperature Range and Limitations

Type J thermocouples have a range of -40°C to 750°C (-40°F to 1382°F). However, they are less stable at high temperatures compared to Type K thermocouples.

Applications of Type J Thermocouples

Due to their iron content, Type J thermocouples work well in ferrous metal applications, such as steel processing and manufacturing. They are also common in older equipment due to their historical use.

Type T Thermocouples: Excellence in Low-Temperature Measurements

Type T thermocouples consist of Copper and Constantan, making them ideal for low-temperature tasks.

Temperature Range and Benefits

They can measure temperatures from -200°C to 350°C (-328°F to 662°F). Their stability and accuracy at low temperatures make them excellent for refrigeration and cryogenics.

Applications of Type T Thermocouples

Type T thermocouples are commonly used in laboratories and food preservation industries where precise low-temperature measurements are critical. Their resistance to corrosion also enhances their versatility.

Selecting Type N Thermocouples for High-Temperature Environments

Type N thermocouples, made from Nicrosil and Nisil, are designed for high-temperature settings.

Temperature Range and Durability

They can measure temperatures from -200°C to 1300°C (-328°F to 2372°F). Type N thermocouples are known for their stability and oxidation resistance, making them ideal for extreme conditions.

Applications of Type N Thermocouples

These thermocouples are often used in aerospace and high-temperature industrial applications, where reliability and accuracy are crucial.

Comparison of Different Types of Thermocouples: Which One to Choose?

Choosing the right thermocouple depends on several factors, including temperature range, environment, and specific application needs.

Key Considerations

| Consideration | Description |

| Temperature Range | Ensure the thermocouple can measure your expected temperatures. |

| Environment | Consider exposure to corrosive materials or extreme conditions. |

| Response Time | Different thermocouples respond at different speeds. |

Summary of Thermocouple Types

| Type | Temperature Range | Material Composition | Best Use Case |

| K | -200°C to 1260°C | Chromel/Alumel | General-purpose, high temperatures |

| J | -40°C to 750°C | Iron/Constantan | Ferrous metals, older equipment |

| T | -200°C to 350°C | Copper/Constantan | Low temperatures, refrigeration, cryogenics |

| N | -200°C to 1300°C | Nicrosil/Nisil | High temperatures, aerospace |

| Type | Temperature Range | Material Composition | Best Use Case | Advantages | Disadvantages |

| K | -200°C to 1260°C | Chromel/Alumel | General-purpose, high temperatures | Wide range, cost-effective, robust | Less accurate at low temperatures |

| J | -40°C to 750°C | Iron/Constantan | Ferrous metals, older equipment | Good for ferrous applications | Less stable at high temperatures |

| T | -200°C to 350°C | Copper/Constantan | Low temperatures, refrigeration, cryogenics | Excellent stability, accuracy at low temperatures | Limited high-temperature range |

| N | -200°C to 1300°C | Nicrosil/Nisil | High temperatures, aerospace | High stability, oxidation resistance | More expensive than other types |

Installation Best Practices for Accurate Temperature Readings with Thermocouples

Proper installation of thermocouples is crucial for accurate readings.

Important Installation Tips

- Correct Placement: Position the thermocouple to accurately measure the temperature of the medium.

- Use Appropriate Insulation: Select insulation that prevents heat loss and ensures accurate readings.

- Avoid Mechanical Stress: Install thermocouples to minimize stress, which can cause inaccurate readings or damage.

Calibration and Maintenance

Regular calibration and maintenance of thermocouples are essential for ongoing accuracy. Monitor your thermocouples and recalibrate them according to the manufacturer’s recommendations or industry standards.

Advanced Technical Information: Calibration and Error Analysis

Calibration methods for thermocouples can vary, but common techniques include:

– Ice Point Calibration: Using the freezing point of water (0°C) as a reference.

– Comparison Calibration: Comparing the thermocouple reading to a standard thermometer.

Error analysis involves understanding potential sources of error, such as:

– Reference Junction Compensation: Ensuring accurate readings by compensating for the temperature of the reference junction.

– Thermal Drift: Monitoring changes in calibration over time due to environmental factors.

Future Trends in Temperature Measurement Technology and the Role of Thermocouples

As technology advances, temperature measurement continues to evolve. Trends include the integration of IoT (Internet of Things) technology for remote monitoring and data collection.

The Role of Thermocouples in Future Technologies

Despite these advancements, thermocouples remain relevant due to their reliability, cost-effectiveness, and adaptability. They are also integrating with smart technologies for better data analysis and enhanced performance.

The Enduring Importance of Thermocouples

Understanding the different types of thermocouples and their applications is essential for anyone involved in temperature measurement. By selecting the appropriate type for your specific needs and following best practices for installation and maintenance, you can ensure accurate temperature readings. As technology continues to advance, thermocouples will likely remain a vital component in temperature measurement solutions.

With this comprehensive overview, you should now have a solid understanding of the types of thermocouples, their applications, and how to select and use them effectively in various scenarios.