On This Page

What is EPDM: A Comprehensive Overview

EPDM is a synthetic rubber made primarily from two monomers: ethylene and propylene, combined with a diene component that enhances its properties. Its flexibility and durability make it suitable for both indoor and outdoor applications.Properties of EPDM

EPDM rubber possesses several key properties that contribute to its popularity:- Weather Resistance: EPDM resists UV radiation, ozone, and extreme temperatures, maintaining its integrity in harsh conditions.

- Chemical Resistance: This material withstands many chemicals, including acids, alkalis, and water, making it suitable for various industrial uses.

- Flexibility: The rubber is elastic and can stretch significantly without losing shape, ideal for many flexible applications.

Common Misconceptions

Several misconceptions about EPDM can lead to confusion:- Not All Rubber Is the Same: People often think of rubber as a single type. EPDM is unique in its formulation and properties compared to natural rubber or other synthetic rubbers.

- Limited to Roofing Applications: While EPDM is well-known for roofing, it has many other applications that are often overlooked.

What is EPDM Rubber Made Of?

EPDM’s unique composition sets it apart from other rubber materials.The Chemical Structure

What is EPDM rubber made of? EPDM consists of ethylene, propylene, and a diene component, which can be either ethylidene norbornene (ENB) or dicyclopentadiene (DCPD). This combination provides a balance between flexibility and durability.- Ethylene and Propylene: These monomers form the backbone of the EPDM polymer, contributing to elasticity and weather resistance.

- Diene Component: The diene enhances the rubber’s cross-linking capability, resulting in improved strength and resilience.

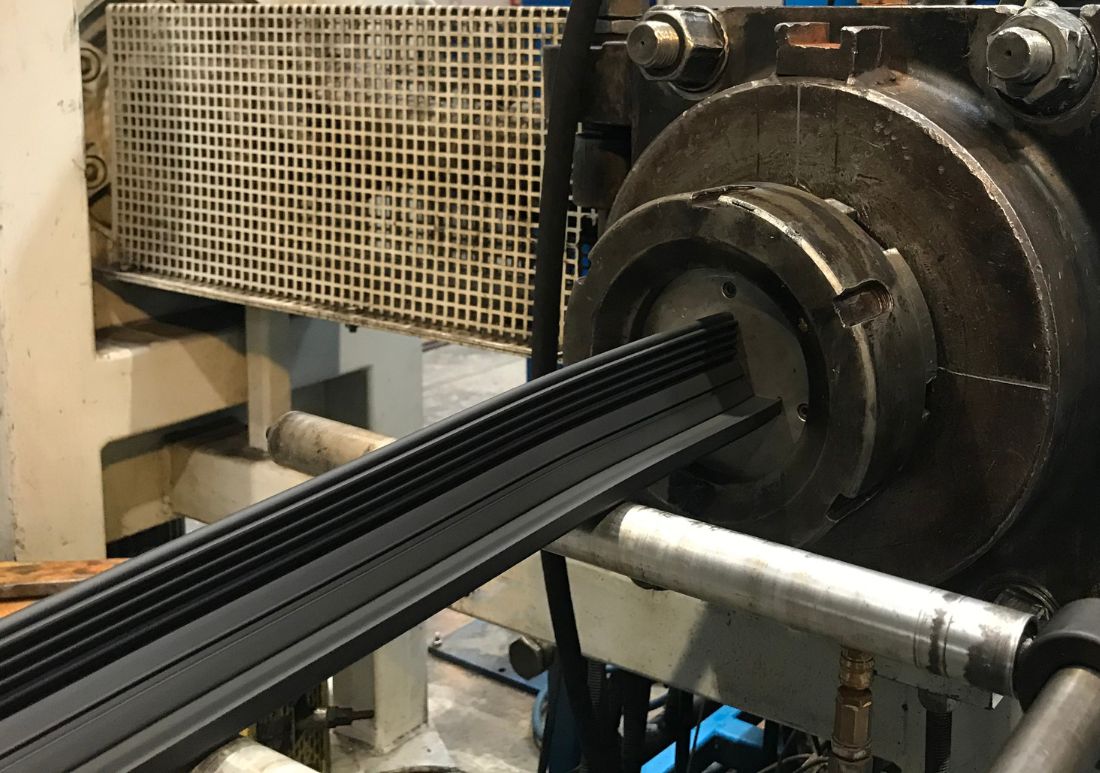

What is EPDM material and its Manufacturing Process

Producing EPDM involves polymerization, where the monomers combine under controlled conditions. This process can create different grades of EPDM, allowing manufacturers to customize the material for specific applications.Key Advantages of Using EPDM in Various Applications

EPDM offers numerous advantages, making it a preferred choice for many applications.Durability and Longevity

One primary reason why EPDM is so relevant is its exceptional durability.- Weather Resistance: EPDM withstands extreme temperatures, from -40°F to 300°F, without degrading, making it suitable for both hot and cold climates.

- Chemical Resistance: Its ability to resist chemicals ensures a longer lifespan in environments where exposure to harsh substances is common.

Cost-Effectiveness

Users often ask what EPDM material is. EPDM is often more cost-effective than other materials due to its longevity and low maintenance needs.- Long Lifespan: With proper installation and care, EPDM products can last 30 years or more, reducing the need for frequent replacements.

- Low Maintenance: EPDM requires minimal maintenance, saving time and money for businesses and homeowners.

Versatility

EPDM’s versatility allows for a wide range of applications, from roofing to automotive parts.- Roofing: EPDM commonly appears in commercial roofing systems due to its waterproof properties and UV resistance.

- Automotive: In the automotive industry, EPDM is used for seals, gaskets, and hoses, leveraging its flexibility and durability.

Personal Experience

In my experience working on commercial roofing projects that utilized EPDM, I observed its remarkable resistance to weathering and wear. One particular project involved a flat roof that had been exposed to extreme temperatures and heavy rainfall. After several years, the EPDM system showed minimal signs of degradation, reinforcing my belief in its long-term reliability.Potential Disadvantages of EPDM: What to Consider

While EPDM has many advantages, it also presents some disadvantages.Limited Ozone Resistance

Although EPDM generally resists ozone, it can crack under certain conditions.- Ozone Exposure: In areas with high ozone levels, EPDM may develop cracks over time, potentially leading to failure if not monitored.

Color Limitations

EPDM typically comes in black, which can be a drawback for some applications.- Aesthetic Limitations: For projects requiring specific colors, EPDM’s limited options can lead some to choose alternative materials.

Installation Challenges

Installing EPDM can be more complex than other materials.- Professional Installation Required: Proper installation is crucial to ensure the longevity and effectiveness of EPDM products. This may require hiring professionals and increasing project costs.

Additional Considerations

- Temperature Sensitivity: EPDM can become less flexible in extremely cold temperatures, which may affect its performance in certain applications.

- Initial Cost: The upfront cost for EPDM materials may be higher compared to some alternatives, although its longevity often offsets this expense over time.

EPDM vs. Other Rubber Materials: A Comparative Analysis

When exploring what EPDM is, comparing it to other rubber materials reveals its unique advantages.EPDM vs. Natural Rubber

- Weather Resistance: EPDM outperforms natural rubber in weather resistance, making it better for outdoor uses.

- Chemical Resistance: EPDM resists chemicals better than natural rubber, which can degrade when exposed to certain substances.

EPDM vs. Neoprene

- Temperature Resistance: Both materials offer good temperature resilience, but EPDM excels in extreme cold conditions.

- Cost: EPDM is generally more cost-effective than neoprene, especially for large-scale applications.

EPDM vs. Silicone

- Heat Resistance: Silicone has higher heat resistance than EPDM, making it suitable for high-temperature applications.

- Flexibility: EPDM is more flexible than silicone, ideal for applications requiring elasticity.

Common Applications of EPDM in Industry and Construction

EPDM sees use in various applications across different industries.Roofing Systems

EPDM is popular in commercial roofing due to its waterproof nature and UV resistance.- Membrane Roofing: Many flat roofs use EPDM membrane systems, which are easy to install and maintain.

- Energy Efficiency: EPDM roofing improves energy efficiency by reflecting sunlight and reducing cooling costs.

Automotive Parts

In the automotive sector, EPDM is used in various components, including:- Seals and Gaskets: EPDM’s flexibility allows it to form tight seals, preventing leaks.

- Hoses: EPDM hoses are used for coolant and other fluids due to their chemical resistance.

Electrical Insulation

EPDM’s insulating properties make it suitable for electrical applications, such as:- Cable Insulation: EPDM insulates electrical cables, protecting them from moisture and environmental damage.

- Connectors: EPDM is often used in connectors to ensure secure and insulated connections.

| Application Area | Specific Uses | Advantages | Considerations |

| Roofing Systems | Membrane roofing, energy-efficient roofs | Waterproof, UV resistant, easy to maintain | Requires professional installation |

| Automotive Parts | Seals, gaskets, hoses | Flexible, chemical-resistant | Variability in lifespan based on usage |

| Electrical Insulation | Cable insulation, connectors | Moisture protection, good insulator | Potential for wear over time |

| Construction | Expansion joints, weather stripping | Durable, versatile | Proper installation is critical |

| Industrial Applications | Hoses, belts, seals | High durability in harsh environments | May require specialized materials for specific chemicals |

Maintenance and Longevity of EPDM Products

Proper maintenance is essential for ensuring the longevity and effectiveness of EPDM products.Regular Inspections

Conduct regular inspections to identify potential issues early.- Visual Checks: Regularly inspect EPDM roofing or other products for signs of wear, such as cracks or tears.

- Cleaning: Keep surfaces clean to prevent debris accumulation that may cause damage.

Repairing EPDM

Prompt repairs are crucial for maintaining the material’s integrity.- Patch Kits: EPDM patch kits are available for repairing small holes or tears, allowing for quick fixes.

- Professional Help: For significant damage, consult professionals to ensure proper repairs.

Lifespan Considerations

With appropriate maintenance, EPDM products can last for decades, making them a worthwhile investment for residential and commercial applications.- Expected Lifespan: EPDM roofing systems typically last 30 years or more, while automotive parts may vary based on usage.